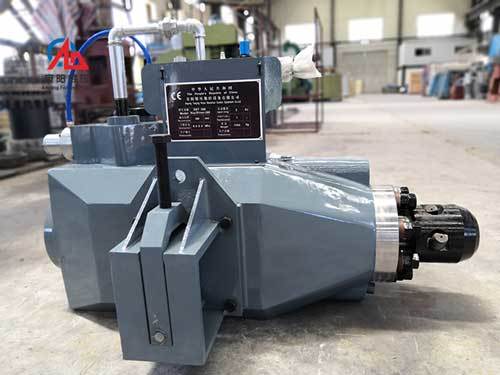

Forging Die Wedge Driver Die Installation Key Driver

Product Details:

- Product Type Forging hammer assistant machine

- Material Steel

- Computerized No

- Control System Human Machine Interface

- Dimension (L*W*H) 60x80x500 Millimeter (mm)

- Weight 860 Kilograms (kg)

- Color customized

- Click to View more

Forging Die Wedge Driver Die Installation Key Driver Price And Quantity

- 1 Set

Forging Die Wedge Driver Die Installation Key Driver Product Specifications

- Steel

- No

- Forging hammer assistant machine

- 860 Kilograms (kg)

- 60x80x500 Millimeter (mm)

- Human Machine Interface

- customized

- 1 year

Forging Die Wedge Driver Die Installation Key Driver Trade Information

- Qingdao port, Shanghai port

- Cash on Delivery (COD) Days after Acceptance (DA) Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Western Union Paypal Delivery Point (DP) Cash Against Delivery (CAD) Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque Cash Advance (CA)

- 50 Set Per Month

- 30 Days

- Contact us for information regarding our sample policy

- wooden cases

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- CE ISO

Product Description

The purpose and significance of key driver

Now in general forging factories, they use drop hammer to drive wedge, this operation has a lot of disadvantages.Generally on one hand, an enterprise has only one hammer to use, no matter how big the wedge is, the striking force and direction can not be controlled, sometimes the force is too big to pull out it, and the wedge is also easy to damage. On the other hand, many people operate it at the same time, which is unsafe, and improper operation will damage other objects.

The key driver (wedge punch tool, wedge punch, bevel punch) produced by Anyang Forging Press Co., LTD. can be used with suitable forklift to drive wedges on forging hammers.The key driver is a pile machine driven by compressed air,the hitting head performs a quick hit with a corresponding strike energy.

Introduction of key driver

- Anyang Key driver (wedge driver) is to be used for the driving in and out of mounting wedges to forge hammers in combination with a suitable and permissible forklift.

- The key driver (wedge driver ) may only be used if it is in impeccable technical condition whilst adhering to all instructions in the operating instructions.

- Starting and operation of the driver is only possible in two-handed operation. The Key/wedge driving machine be operated by only one operator.

Compressed air supply for Key/wedge driver

Compressed air supply shall be guaranteed to be clean, dry, and own continuous pressure as possible.If air is moist, installing a deflector in front of injector to protect the wedge tools from rust.

Usage and energy adjustment of key driver

- The slide valve is the central control element for adjusting the wedge tool.Different functions can be achieved by adjusting rotary slider manually.

- Position Z: in this position, the compressed air cannot pass through the control valve, so the piston has different air.

- Position E: in this position, the compressed air of the wedge tool is stored after the air supply is disconnected.

- Position 1-6: strike energy is adjusted from light to heavy by position 1-6.

- Position 6 is the maximum cross-section that allows compressed air to pass through, at which point the wedge tool strikes with maximum strike energy.

How to use Key driver machine

Adjusting the wedge tool to the wedge,and the positions of forklift and wedge tool, make the stroke shaft of the wedge and wedge tool to be concentric. According to the requirements of each type parameters, adjust the distance between the impact head of wedge tool and the wedge.

Premise of safe operation of wedge tools

- The working area shall be completely isolated from the area behind the machine (forging hammer)

- No one behind the machine

- Only forklift drivers and operators can be in isolated areas

- Operators must wear the required protective clothing

- Only operators can be at the inside danger zone.

Key driver technical parameter:

|

Item |

Unit |

DXT-100 |

DXT-200 |

DXT-400 |

DXT-800 |

|

Max impact Energy |

KJ |

1 |

2 |

4 |

8 |

|

Pressurised Air Connection |

Inch |

1 |

1 |

1 |

1 And Half |

|

Max Wedge Dimension |

mm |

60x80x500 |

80x120x1000 |

100x200x2000 |

All the Wedges |

|

Working Pressure |

MPa |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

|

Max Piston Stroke |

mm |

400 |

500 |

600 |

700 |

|

Weight (Including Bracket) |

Kg |

860 |

1560 |

2860 |

5500 |

|

Matched Forging Hammer Hit Energy |

KJ |

0-20 |

25-75 |

75-150 |

150-500 |

Other Products in 'Key Wedge Driver' category

|

ANYANG FORGING PRESS MACHINERY INDUSTRY CO., LTD

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry